Pump with Piston: An Essential Component for Various Industries

Pump with Piston: An Essential Component for Various Industries

Introduction:

The pump with piston is a crucial piece of equipment used in numerous industries. Its ability to move fluids efficiently and effect pump with piston ively makes it an indispensable tool. In this article, we will explore the manufacturing process, characteristics, advantages, application methods, tips for selecting these products, and conclude their significant role in vari Airless pump bottle factory ous industries.

Manufacturing Process:

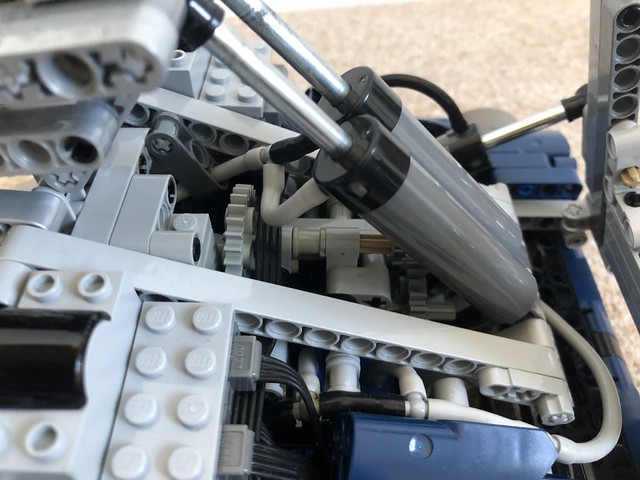

The pump with piston is primarily known as a double-acting piston pump or a positive displacement pump with a piston. It operates on the principle of reciprocation using hydraulic power and consists of several critical components like the cylinder pump and plunger pump. To manufacture these pumps, specialized factories utilize precision engineering techniques combined with high-quality materials to ensure optima

l performance.

Characteristics:

1. Efficiency: The efficient design allows for smooth fluid transfer without leakage or loss.

2. Versatility: Pump with pistons can handle various types of liquids ranging from thin solvents to thick viscous mate Airless pump bottle vendors rials.

3. Durability: These pumps are designed to withstand extreme conditions and operate continuously without compromising performance.

4. Precision Control: With adjustable Double-acting piston pump stroke length settings and accurate pressure regulation mechanisms, these pumps offer precise control over fluid flow.

Advantages:

1. Consistent Pressure: The double-acting feature enables constant pressure output even during alternating strokes.

2. High Flow Rates: Pumping large volumes quickly is achievable due to the nature of positive displacement pumping.

3. Suitable for Sensitive Fluids: Being leak-free ensures that delicate or volatile substances remain unha Airless pump bottle vendors rmed during transfer.

Using the Pump with Piston:

To use a pump with a piston effectively:

1.Step 1 – Connect appropriate inlet/outlet fittings based on fluid requirements.

2.Step 2 – Prime the system by filling liquid into both sides of the cylinder alternately if necessary.

3.Step 3 – Start hydraulic power source (motor o pump with piston r hand lever) as per pump specifications.

4.Step 4 – Ensure the pressure is within the desired range before initiating pumping action.

How to Select Pump with Piston:

1. Consider Fluid Type: Different pumps are designed for different fluid viscosities and chemical compatibility; choose accordingly.

2. Flow Rate Requirements: Determine the required flow rate and s Positive displacement pump with piston elect a pump that meets or surpasses it.

3. Pressure Needs: Assess the ma Hydraulic reciprocating pump ximum pressure output necessary for your application and choose a pump capable of achieving that level.

4. Construction Material: Evaluate if the materials used in manufacturing align with any specific environmental concerns, such as corrosive substances.

Conclusion:

The pump with piston plays a vital role across multiple industries due to its efficient design, durability, versatility in handling various fluids, and precise control over flow rates and pressures. It enables consistent pumping action while offering benefits like high flow rates, leak-free operation, and suitability f pump with piston or sensitive liquids. When selecting these pumps, considering factors like fluid type, flow rate requirements, pressure needs, and construction material will ensure optimal performance in specific applications. To conclude,

having a reliable pump with piston solution is essential for industries seeking efficient fluid transfer capabilities.