Hydraulic Reciprocating Pump: The Perfect Choice for Efficient Fluid Transfer

Hydraulic Reciprocating Pump: The Perfect Choice for Efficient Fluid Transfer

Introduction:

In the field of fluid transfer, there are various types of pumps available

to meet different requirements. One such pump is the hydraulic reciprocating pump, specifically designed with a piston mechanism to en

sure precise and efficient fluid movement. In this article, we will explore the manufacturing process, features, advantages, usage methods, tips for selecting this product and draw conclusions on its suitability for various applications.

Manufacturing Process:

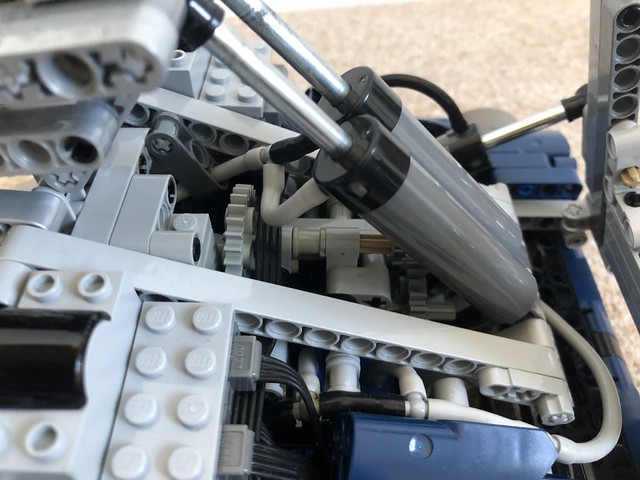

The hydraulic reciprocating pump consists of several key components including the cylinder pump and double-acting piston pump with piston pump. These parts are precision-engineered using high-quality materials such as heavy-wall PET bottles that provide durability and strength required for lon

g-term use. The assembly process involves meticulous attention to detail in order to ensure optimum performance during operation.

Features:

One of the prominent features of a reciprocating pump is its ability to deliver fluids in controlled quantities due to positive displacement from the piston mechanism. This ensures accurate measurement and avoids wastage or spillage during transfer operations. Moreover, the heavy-wall pump with piston PET bottle design provides excellent resistance against corrosion even when handling aggressive chemicals or liquids.

Advantages:

The hydraulic reciprocating pump offers numerous advantages over other conventional pumps currently avail Positive displacement pump with piston able in the market. Firstly, it delivers consistent pressure throughout each stroke cycle due to its unique design incorporating a piston-driven mechanism. Secondly, it requires minimal maintenance owing to its robust construction involving high-quality materials heavy-wall PET bottle known for their resilience and reliability.

Usage Methods:

To operate a hydraulic reciprocating pump efficiently, certain guidelines need consideration. Prior priming is essential before initiating pumping operations as Hydraulic reciprocating pump it helps remove any air bubbles trapped within the system which may affect overall performance. Additionally, regular inspection intervals should be maintained alongside routine lubrication procedures defined by manufacturers’ recommendation pump with piston s for maximum efficiency.

Selecting Hydraulic Reciprocating Pumps:

When selecting this type of pump suitable for your specific application, several aspects come into play. Firstly, consider the intended purpose and fluid compatibility with the heavy-wall PET bottle materials Cylinder pump used in its construction. Secondly, assess the required flow rate and pressure capacity based on your specific needs.

Conclusions:

The hydraulic reciprocating pump is an excellent choice for industries requiring precise fluid transfer due to its uni heavy-wall PET bottle que design and features such as positive displacement and double-acting piston mechanism. Its efficient manufacturing process ensures durability even when handling aggressive fluids or chemicals. By following proper usage methods and considering key selection factors, users can effectively utilize this pump in their applications while achieving optimal results.

In summary, hydraulic reciprocating pump with piston pumps offer a reliable solution that combines accuracy, efficiency, durability, and versatility for various industries’ fluid transfer requirements.